The iron and steel industry is a typical energy and resource-intensive industry. Iron and steel production consumes a lot of energy and resources, and at the same time generates a lot of industrial solid waste. If the solid waste cannot be properly handled, it will not only bring huge pressure to the regional ecological environment, but also cause a huge waste of resources.

In recent years, my country has introduced a series of industrial policies to support the development of the solid waste resource recycling industry; various localities have also introduced related policies to promote energy conservation, emission reduction, and green transformation in the steel industry. The issuance and implementation of a series of related policies provide policy support, technical direction and economic guidance for the comprehensive development and utilization of industrial solid waste resources in the iron and steel industry, clarify the development direction of the comprehensive resource utilization industry, and promote the comprehensive utilization of solid waste resources in the iron and steel industry Towards the direction of specialization, scale and high value.

At present, the steel smelting process has basically achieved standard production. Among them, the waste water is 100% recycled, the exhaust gas reaches the national ultra-low emission standard, and the comprehensive utilization of iron and steel metallurgical solid waste such as iron and steel dust and sludge has become a key issue that restricts the sustainable development of iron and steel green recycling. Strengthening concept innovation, strengthening scientific research and development, implementing green transformations, and strengthening solid waste management can improve the comprehensive utilization of solid waste throughout the entire process of the iron and steel industry, and promote the rational extension of the iron and steel industry chain towards zero emissions. Therefore, the implementation of the concept of "solid waste of iron and steel does not leave the factory" has very strong practical significance for the green development of the steel industry, zero growth of solid waste, and energy saving and emission reduction. It is also an inherent requirement for the sustainable green development of the steel industry. This article introduces in detail the causes, classification, and resource utilization methods of steel dust and sludge.

There are many types of steel dust

There are many types of solid waste in the iron and steel industry, mainly including blast furnace slag, steel slag, metal-containing dust sludge, desulfurization gypsum, desulfurization ash, and ferroalloy slag. Among them, the largest amount of solid waste is smelting slag, followed by dust and mud. In 2019, my country's crude steel output was about 996 million tons, and steel dust was calculated at 10% of crude steel output to be about 99.6 million tons.

Steel dust and sludge come from the production workshop of steel, generally refers to the waste generated after the high-temperature flue gas is dedusted by the dust removal facility in the production processes of raw material processing, sintering, pelletizing, ironmaking, steelmaking, and subsequent processing links , The waste generated in the cleaning process, etc. According to the generation of dust and mud, the dust and mud mainly include the dust and mud collected by the dust collector during the transportation and sintering process (sintering dust, mud), and the dust and mud collected during the purification process of blast furnace gas (blast furnace gas ash, blast furnace gas mud) ), dust and sludge collected by converter steelmaking gas dust (converter dust or sludge), dust and sludge collected by electric furnace steelmaking flue gas (electric furnace dust or sludge), iron oxide scale peeled off during steel rolling, steel rolling wastewater In the recycling process, the sludge recovered in the sedimentation tank (secondary sludge from steel rolling), the subsequent processing of steel billets or steel and the dust and sludge accumulated during the cleaning process, etc.

Among them, environmental dust removal mainly includes unloading on the tank, rotating derivatives of the belt conveyor, screening under the tank, loading of raw materials into hoppers, collection hoppers, etc. The concentration of dust is 5 g/m3 ~ 8 g/m3.

Sintering dust sludge is mainly the dust ash produced in the sintering process, including the dust ash from the machine head flue gas, the ore ash from the machine tail, etc. The output is about 0.9 kg/ton pig iron to 15 kg/ton pig iron.

The amount of blast furnace dust (gas ash, gas mud, dust removal ash) produced is about 9 kg/ton pig iron ~ 22 kg/ton pig iron. When the ironmaking raw materials contain a certain proportion of zinc metal, 95% to 98% of the zinc metal enters the dust and mud in the form of volatiles, and the zinc content of the dust and mud is 20 to 30 times that of the raw materials.

The output of converter dust and mud is about 9 kg/ton steel to 15 kg/ton steel. Due to the high temperature conditions of part of the scrap steel and the converter, when the scrap steel is returned to the converter for regeneration, metals such as zinc and iron enter the dust and mud, and the iron content in the dust and mud is high.

Electric furnace (EAF) dust output is about 16 kg/ton steel ~ 20 kg/ton steel. The galvanized scrap of electric furnace steelmaking raw materials is relatively large, and most of the zinc metal in the scrap returns to the dust and mud under high temperature conditions, resulting in a high zinc content in the dust and mud. The content of zinc and iron in the dust and mud of different steel scrap varieties are also different.

Other dust and mud, such as under-sieve dust, iron oxide scale, and oily sludge generated during steel rolling, as well as dust and waste mud generated during forging, cutting, welding, pickling and other subsequent processing and cleaning processes.

From the perspective of the production of steel dust and mud, it has four main characteristics: one is diverse sources and large output; second, complex composition, low content and large fluctuations; third, small particle size, high pollution hazards; fourth, resource utilization The potential value is great.

The existing treatment methods of steel dust and mud have certain limitations

At present, the treatment methods of steel dust and sludge are mainly storage and landfill covering and returning to the blast furnace for sintering. Stockpiling not only takes up a lot of land and pollutes the ecological environment, but also causes a lot of waste of resources. In 2019, the amount of steel dust and mud produced in my country was about 100 million tons, calculated on the basis of 50% of the stockpile, occupying more than 2500 acres of land.

If it is simply processed through the sintering or pelletizing process and then enters the blast furnace again, it will cause the metal elements such as zinc in the dust and mud to be cyclically enriched in the blast furnace, which will adversely affect the iron-containing charge, coke and the refractory lining of the furnace, and then damage The stability of the blast furnace will shorten the service life of the blast furnace and increase the production cost of the enterprise. For example, once zinc metal and alkali deposit excessively on the surface of the furnace lining, it is easy to produce furnace nodules, hinder the smooth decline of the charge, and even lead to the occurrence of material suspension. If zinc metal and alkali deposit excessively inside the furnace lining, it is easy to cause the furnace lining to expand significantly and be damaged; if zinc metal and alkali accumulate excessively at the tuyere, it is easy to burn the air supply equipment such as the tuyere. According to relevant statistics, the age of the furnace may decrease by 2 More than years.

In addition, my country’s iron and steel solid waste resource utilization has problems such as high equipment energy consumption, low resource recovery rate, and few resource recovery varieties. Many iron and steel enterprises have selectively recycled a small amount of iron and steel metallurgical solid waste, or Set up a dedicated place for storage or external sale. For the steel industry itself, it is urgent to seek advanced metal dust and sludge treatment technologies such as iron and zinc to solve the problems of land occupation of dust and sludge waste, environmental pollution, resource waste, and difficulty in recycling.

The resource utilization of steel dust and mud is of great significance

Support the iron and steel industry to achieve high-quality green and circular development. Steel smelting and processing enterprises strengthen solid waste management, alleviate the problem of comprehensive solid waste utilization, improve the efficiency of comprehensive solid waste utilization, and promote the recycling of solid waste resources. This is not only the inclusive and coordination of enterprises and cities, but also the only way to achieve high-quality development of green recycling. .

Helping the transformation and upgrading of the steel industry cluster cities and economic structural adjustment. Iron and steel solid waste is a treasure left over in the historical development of resource-based cities, and it is also an important starting point for the transformation and upgrading of steel-aggregating cities under the background of the new era. The state has issued a series of policy encouragement documents and related restrictive measures for the comprehensive utilization of steel solid waste, which has pushed the steel industry to a green and circular development from two levels of positive encouragement and reverse force. In the future, my country will put forward higher standards and stricter requirements for the comprehensive utilization of various solid wastes. A number of restrictive measures will provide major opportunities for local development of the comprehensive utilization of industrial resources, and also cater to the urgent requirements of industrial transformation and upgrading in steel-aggregated cities.

Replenish resources effectively. my country's high dependence on foreign iron ore affects my country's resource security to a large extent. In addition to a large amount of iron, iron and steel dust also contains many valuable metal elements, such as chromium, manganese, nickel, copper, cobalt, vanadium, molybdenum, niobium, zinc, potassium, sodium, gold, silver, indium, etc. The scientific extraction of valuable metal elements can effectively supplement the primary resources such as iron ore, manganese ore, nickel ore, chromium ore that my country depends on imports, and molybdenum ore and vanadium ore that are difficult to mine.

Urgently seeking a new resource utilization process of steel dust and mud

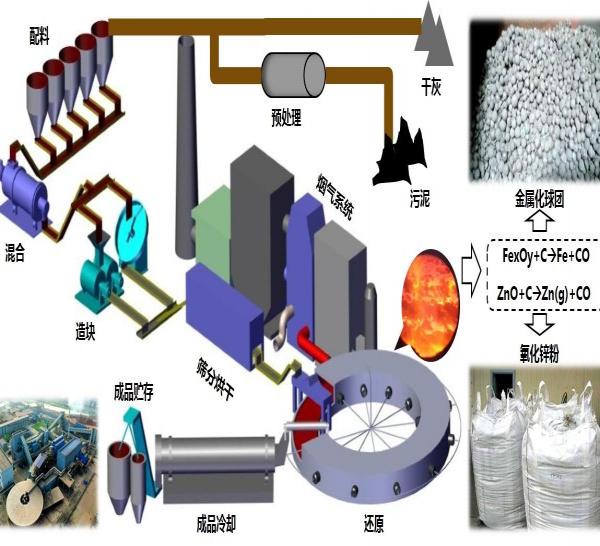

At present, my country's conventional treatment processes for steel dust and sludge mainly include physical methods, wet methods, and fire methods. The physical method mainly includes magnetic separation and hydraulic spiral flow separation; wet method is the use of acid leaching, alkali leaching or leaching + roasting and other processes to treat steel dust and sludge; fire methods mainly include sintering method, pellet method, and direct reduction method ( Rotary kiln and rotary hearth furnace processing technology, etc.), smelting reduction method.

The process of treating steel dust and sludge by physical method is relatively simple. The disadvantage is that the enrichment rate of zinc and other metals is low, and the zinc content of zinc-rich products is too low and the value is small. The general physical method is only used as a pretreatment process for wet or fire processes. The wet process equipment is corroded seriously, most of the operating conditions are harsh, and the production efficiency is low, which does not match the dust and mud output of steel enterprises. The pyrotechnical process is the main way to select steel dust and sludge resource utilization due to its high efficiency and large-scale treatment of steel dust and sludge.

In the pyrotechnic process of the resource utilization of steel dust and mud, the product of the rotary hearth furnace process is metalized pellets, which has the disadvantages of low grade of iron and other metals and large amount of slag. The rotary kiln is prone to ring formation during use, the maintenance cost is high, the reduction time is long, and the requirements for the process conditions are relatively strict. Smelting reduction technology has attracted much attention due to its advantages such as wide adaptability of raw materials and low strength requirements of charge.

In the face of the new situation where my country's energy, resources, environment and other pressures are increasingly prominent, the steel industry's emphasis on the efficient use of solid waste resources is a key and inevitable choice for achieving green and sustainable development. The steel dust and sludge resource utilization technology with better investment economy, better environmental protection, and higher resource efficiency is not only imminent but also of great significance for iron and steel metallurgical enterprises including stainless steel. It is also endowed by the times and the environment forces steel. The new requirements of the industry.

Post time: Jul-23-2021